Home / All / Dust Collection Auxiliary Equipment /

Cylindric Round Pulse Jet Dust Collector for High Pressure Resistance

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Cylindric Round Pulse Jet Dust Collector for High Pressure Resistance

| Categories | Dust Collection Auxiliary Equipment |

|---|---|

| Brand | ACMAN |

| Model | Alpha-X |

| Application | Industrial Dust Collection/Powder Recycle |

| Filter Material | Polyester Cartridge Pleated Filters |

| Cleaning Mode | Pulse jet compressed air backflow |

| Compressed Air Source | 0.4-0.6MP |

| Jet Control | Timer/pulse controller |

| Power Supply | 380V/50HZ or Customize |

| FOB port | SHANGHAI/NINGBO |

| Terms of Payment | T/T |

| Update Time | Apr 19,2025 |

Detail Information

Cylindric Round Pulse Jet Dust Collector for High Pressure Resistance.

Alpha filter unit is a dry filter system designed for a high pressure working condition, as we all known, round design could resist high pressure when the end centrifugal fan's pressure is super high, for example roots blower.

Further more, the round design dust collector could applied in the dust recycle application, the inside could make mirror surface.

The filter unit is a round filter with a welded design, suitable for an operating pressure of +/- 10000Pa.

The Alpha dust collection equipment also have pulse-jet cleaning system to keep the filters in stable pressure and let the powder recycle make sense.

Filters have two choice: cartridge polyester filters and sintered filters.

Factory manufacturing

Working Principle

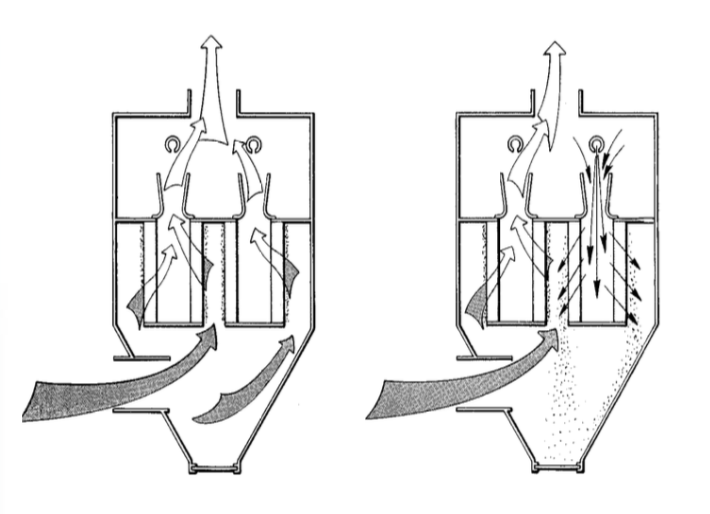

Normally, the raw gas will come into the dust collector body. Because of the weight, filter's crash, hook...

the dust will be blocked by the cartridge filters or filter bags. The clean air will be extracted out of the dust collector by the centrifugal fan who is setting behind the dust collector;

Then, the filter's pressure will high because of the dust cake on the filter surface, at this time the dust collector's efficiency growing high, that is what we said"deep filtration". but, when when the filter's pressure meeting the summit of the pressure setting, the Pulse-jet system will working, and compressed air will back flow inside of the filters, and the dust sticky on the surface of filters will falling into the dust bin or dust hood.

Video

Contact Us

Wechat

+86 19550289881

Info@dustscrubber.com

+86 18768123711

Related Products

Please send your message to us

- Tel

- *Title

- *Content

Love discounts? Subscribe to newsletter!

subscription

Send Inquiry

Please send your message to us

- Tel

- *Title

- *Content

Company

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Web