Home / All / Industrial Centrifugal Fan /

Centrifugal Inline Fan for HVAC Ventilation with AMCA/TUV/CE/ATEX Certificates

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Centrifugal Inline Fan for HVAC Ventilation with AMCA/TUV/CE/ATEX Certificates

| Categories | Industrial Centrifugal Fan |

|---|---|

| Brand | ACMAN |

| Model | ISQ/Duct Fan |

| Update Time | Apr 25,2025 |

Detail Information

Centrifugal inline fan for HVAC ventilation with AMCA/TUV/CE/ATEX certificates

Airflow Range: 600~50,000 m³/h (353~29,412 CFM)

Static Pressure Range: 500~900 Pa (2~3.61 in.WG)

Drive Types: Direct/ Belt drive

Mounting Types: Base mounted/ Ceiling hung/ Duct mounted

Applications: Ducted air supply and exhaust / Filtered air supply and exhaust / Sound-proof fan box / Explosion-proof air supply and exhaust / Smoke removal

-- Excellent aerodynamic characteristics and noise characteristics.

-- High-efficient area width without overloading.

-- Balance quality grade up to G2.5(Typical products are balanced to G6.3 only).

• Air performance design

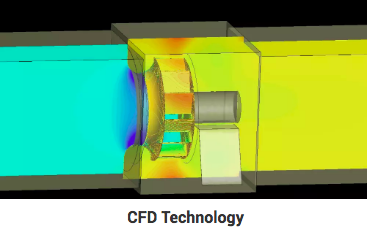

-- Optimized design of CFD flow field simulation,repeatedly validated.

-- Front disc and inlet venture tube according with flow field characteristic.

-- Flow passage control:matched each other to restrain the air flow better.

-- Optimize the blade angles.

• Structure performance design

-- Stress analysis of FEA to improve performance.

-- Selected the strengthen structure according to different specifications to improve reliability.

-- Using riveting technology to avoid stress.

• Improved wheel

-- Continues improvement:The wheel has the 4th generation.

-- Compared with the 3rd generation:Performance increased by 5-10% in the same parameters.

-- Compared with the 3rd generation: Noise reduced 2-3 dB(A)in the same parameters.

• Advanced process

-- Inlet venture tube & Front disc:spun process to ensure streamlines aerodynamic characteristics.

-- Inlet venture tube: replace bell mouth to ensure smooth air flow.

-- Blades:once punch forming to ensure process quality.

-- Tooling:dedicated fixture to ensure precise install of the blades.

Product Feature

• Wide performance range and more economic

-- 4th Generation Wind-surfer Centrifugal Wheel: low noise while pressurizing compare with 3rd generation.

-- Maximum wheel diameter is 1 meter,reduce fan quantity and primary investment.

-- The scroll is saved and the cabinet size is reduced.

• Centrifugal in-line:obvious advantage in RPM and noise

-- Compare with axial/mixed flow fans rotation speed is reduced 20-30%.

-- The sound pressure level range reduced by 10-15 dB(A).

-- Fundamental way to reduce noise.

• Plug fan structure

-- Plug fan directly suck air into wheel and pressurize:air flow pattern improved.

-- Direct drive no dust generated:suitable for clean rooms of wafer fab,pharmaceutical and food industry.

-- AMCA Seal:sound and air performance certified.

-- The sound & air performance is approved by AMCA.

• Sound & Air Performance Seal is applied to each fan

-- Square casing with multi-discharge,easier to connect.

-- Square inlet/outlet sleeve flange as standard accessories :round/square convention duct is not needed.

-- Duct connection cost reduced ,and job site working time saved.

-- Motor can be multi-position.

-- Multi-discharge:More convenient and flexible for design & construction.

-- 4th Generation Wind-surfer Centrifugal Wheel: low noise while pressurizing compare with 3rd generation.

-- Maximum wheel diameter is 1 meter,reduce fan quantity and primary investment.

-- The scroll is saved and the cabinet size is reduced.

• Centrifugal in-line:obvious advantage in RPM and noise

-- Compare with axial/mixed flow fans rotation speed is reduced 20-30%.

-- The sound pressure level range reduced by 10-15 dB(A).

-- Fundamental way to reduce noise.

• Plug fan structure

-- Plug fan directly suck air into wheel and pressurize:air flow pattern improved.

-- Direct drive no dust generated:suitable for clean rooms of wafer fab,pharmaceutical and food industry.

-- AMCA Seal:sound and air performance certified.

-- The sound & air performance is approved by AMCA.

• Sound & Air Performance Seal is applied to each fan

-- Square casing with multi-discharge,easier to connect.

-- Square inlet/outlet sleeve flange as standard accessories :round/square convention duct is not needed.

-- Duct connection cost reduced ,and job site working time saved.

-- Motor can be multi-position.

-- Multi-discharge:More convenient and flexible for design & construction.

ACMAN Research Institute masters a set of core CFD technology combining theory with practice owned by ACMAN itself. In combination with our internationally accredited precision laboratories, aerodynamic parameters of the wheels and housing sizes are repeatedly optimized to pursue better air performance and sound, and now the wheels are updated to the fourth generation.

In the practice process of FEA technology for many years, ACMAN has accumulated a lot of data and experience which are suitable for actual physical property of common materials. To ensure fan unit and all core parts highly reliable, ACMAN has done huge computer simulation tests by FEA and actual tests to verify design parameters on our over speed, vibration and durability test platforms.

Contact Us

Wechat

+86 19550289881

Info@dustscrubber.com

+86 18768123711

Please send your message to us

- Tel

- *Title

- *Content

Love discounts? Subscribe to newsletter!

subscription

Send Inquiry

Please send your message to us

- Tel

- *Title

- *Content

Company

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Web