Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Cyclone Dust Collector Cyclone Separator

| Categories | Cyclone Dust Collector |

|---|---|

| Brand | ACMAN |

| Application | Industrial Dust Removing |

| Air Volume | 370~14630 (m³/h)for choice |

| Diameter | Φ200-Φ1000 (mm) for choice |

| Factory Direct Sale | Yes |

| Delivery | 10-15 days |

| Sea Port | Shanghai/Ningbo |

| Update Time | Jan 28,2025 |

Detail Information

Video

Cyclone Dust Collector Detail:

• Features:

1:Simple in structure, easy in maintenance

2:Low in cost, long service life

3:Good separation effect for coarse dust particles

4:Preliminary treatment for multi-stage dust removing

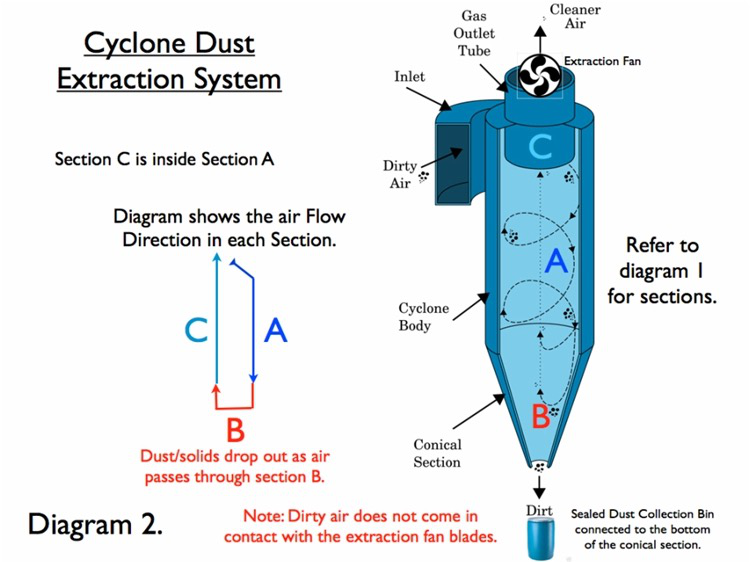

• Peration principle:

Cyclone dust remover is a dry gas-solid separation device that separates dust powder from air stream by using centrifugal force generated by revolving dust air. Cyclone dust remover is easy in structure and manufacturing and low in cost and running cost. It has high filtering efficiency for coarse dust particles that have a diameter more than 5u m, but it has low filtering efficiency for fine dust particles that have a diameter less than 5u m ( especially fine dust particles with low density). So cyclone dust remover is often used for preliminary treatment on coarse dust powder purification or multi-stage purification. XP type cyclone dust remover is applicable to common dust removing and material recovery from industrial waste gas in general industries, not applicable to sticky dust.

• Applicable fields:

It's applicable to mines, metallurgy, fireproof materials, building materials, coal, chemical industry and power industry.

SPECIFICATION PARAMETER

Mode | Air Volume(m³/h) | Parameter(mm) | Weight(Kg) | Resistance(Pa) | Velocity(m/s) |

XP-200 | 370~590 | Φ200×940 | 37 | 880~2160 | 14~22 |

XP-300 | 840~1320 | Φ300×1360 | 51 | 880~2160 | 14~22 |

XP-400 | 1500~2340 | Φ400×1780 | 85 | 880~2160 | 14~22 |

XP-500 | 2340~3660 | Φ500×2200 | 132 | 880~2160 | 14~22 |

XP-600 | 3370~5290 | Φ600×2620 | 183 | 880~2160 | 14~22 |

XP-700 | 4600~7200 | Φ700×3030 | 252 | 880~2160 | 14~22 |

XP-800 | 5950~9350 | Φ800×3450 | 325 | 880~2160 | 14~22 |

XP-900 | 7650~11890 | Φ900×3870 | 400 | 880~2160 | 14~22 |

XP-1000 | 9340~14630 | Φ1000×4280 | 500 | 880~2160 | 14~22 |

OPERATION PRINCIPLE

PRODUCT FAQ:

Q: What dust is suitable for cyclone separator?

A: The Cyclone can be used in almost any application that generates dust particles greater than 20 microns in diameter. Use the Cyclone as your primary collector, with or without the optional after- filter, for dusts of moderate to coarse particle size.

Q: What is the cyclone working principle?

A: Air is suck into the Cyclone tangentially and rotates at high velocity around the inner circumference. The heavier dust is separated from the air by centrifugal action and is deposited in the barrel or hopper.

Q: What is the maintenance and replacement of cyclone?

A: Unlike many dust collectors, the Cyclone contains no moving or replaceable parts and is essentially maintenance free.

Customer Application

Contact Email: Info@dustscrubber.com

Related Products

Please send your message to us

- Tel

- *Title

- *Content

Love discounts? Subscribe to newsletter!

subscription

Send Inquiry

Please send your message to us

- Tel

- *Title

- *Content

Company

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Web