Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Dust Collector/Deduster/Extractor

| Categories | Solder/Welding Fume Extractor |

|---|---|

| Brand | ACMAN |

| Model | TC |

| Application | Industrial Dust/fume Extraction |

| Filter Material | Polyester Cartridge Pleated Filters |

| Cleaning Mode | Motor Shaking |

| FOB port | SHANGHAI/NINGBO |

| Terms of Payment | T/T |

| Update Time | Apr 25,2025 |

Detail Information

Mobile Dust Collector Detail:

• Features:

1:Submicron cylinder filtering, easy for replacement

2:Easy in operation and maintenance

3:Designed on load-and-go basis

4:Automatic off-line dust removing

5:Multiple to be connection locations for air inlets and outlets

6:Easy for transportation

• Operating:

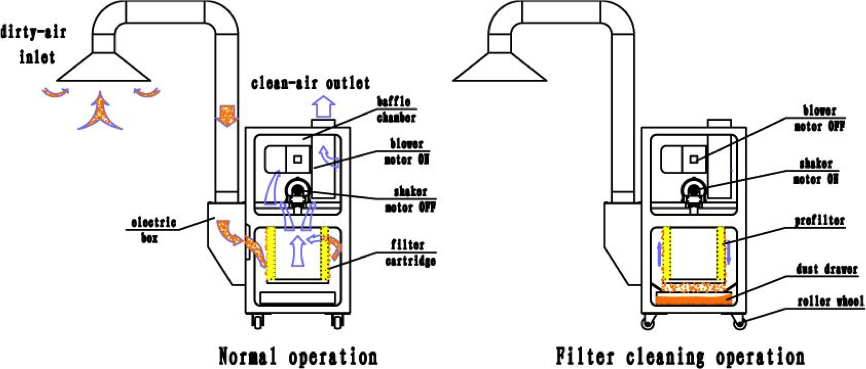

Normal operation: switch on the power, turn on the fan, dust air enters the cylinder from dust source through suspended hood, air hose and air inlet. Flow rate drops suddenly due to air stream soaring; big grain dust separates from dust air and than sink into dust storage tan k, other small grain dust remains at the outer well of filter element under the influence of filtering, colliding, hooking and static electricity. Purified air is discharged from the fan to air outlet via the anechoic chamber above. Dust cleaning operation: dust cleaning goes on discontinuously; high-frequency vibration will enable the filter to regenerate after the fan shuts down.

• Applicable fields:

Application environment: temperature: -10-55 centigrade, relative air humidity no higher than 85%, without compressed air source; Application industry: chemistry industry, pharmaceutical industry, food processing, metal processing, compound material, electronics, building materials, electrostatic coating and other fine air particles.

SPECIFICATION PARAMETER

Model | Air Flow(m3/h) | Pressure(Pa) | Noise(db) | Efficiency | Size | Power(kw) |

TUOER-6C | 500~700 | 1100 | ≤45 | 99.99 | 430×550×700 | 0.55 |

TUOER-8C | 700~900 | 1100 | ≤45 | 99.99 | 540×580×800 | 0.75 |

TUOER-10C | 900~1100 | 1360 | ≤50 | 99.99 | 540×580×900 | 0.75 |

TUOER-12C | 1100~1300 | 1360 | ≤55 | 99.99 | 580×650×1000 | 1.1 |

TUOER-14C | 1300~1500 | 1360 | ≤55 | 99.99 | 580×710×1000 | 1.1 |

TUOER-16C | 1500~1800 | 1580 | ≤58 | 99.99 | 650×890×1050 | 1.5 |

TUOER-18C | 1800~2100 | 1740 | ≤60 | 99.99 | 650×930×1100 | 1.5 |

OPERATION PRINCIPLE

PRODUCT FAQ:

Q: What should provide when choosing suitable dust collectors?

A: Process summary sheet should be provided, for we need to know the dust collection summary for example: dust category (what? Flammable? Corrosive? Explosive? Temperature? Density?)

Q: What is the dust suction hood’s size?

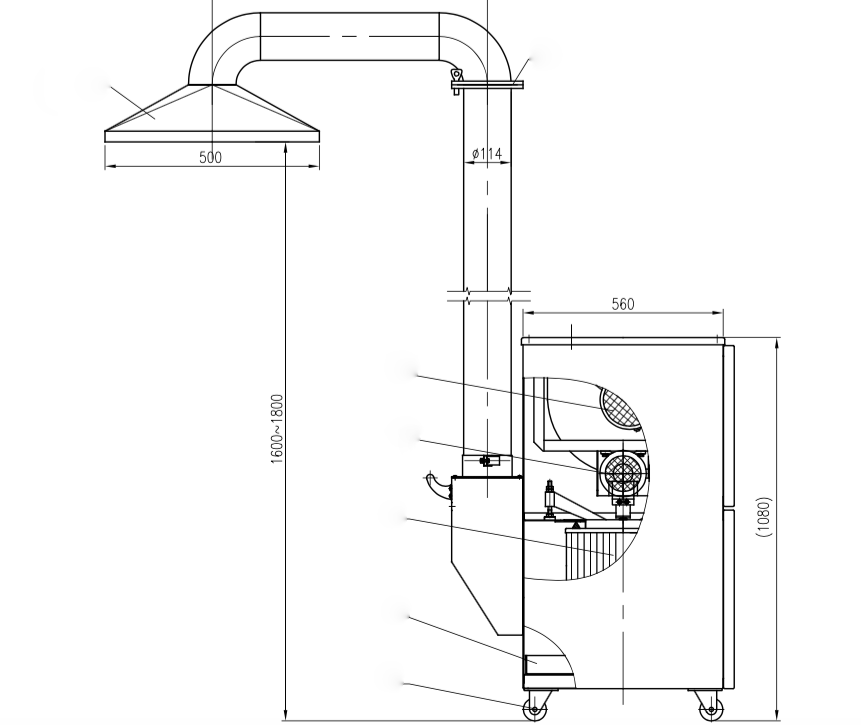

A: Round size 50mm, and the hood is 1600mm-1800mm from the ground and it can adjust 200mm of the height, and the hood can flexible 360 degree rotation.

Q: What type of dashing modes the de-duster provides?

A: Mechanical vibration dust cleaning.

Q: The dust collection unit’s power supply?

A: Every country have different industrial power supplies, we could OEM the blower for your needs.

Contact Email: Info@dustscrubber.com

Please send your message to us

- Tel

- *Title

- *Content

Love discounts? Subscribe to newsletter!

subscription

Send Inquiry

Please send your message to us

- Tel

- *Title

- *Content

Company

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Web