Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Central Downflow Cartridge Dust Collector

| Categories | Industrial Pulse Jet Dust Collector |

|---|---|

| Brand | ACMAN |

| Update Time | Apr 25,2025 |

Detail Information

VIDEO

Central Dust Collector Detail:

• Features:

• Lower initial cost per cubic meter of air per hour (m3/h) / cubic foot of air per minute (cfm)

• Higher filtration efficiency—cleaner gas/air

• Lower pressure lose—greater power and energy savings

• Fewer cartridges change out

• Reduced cartridge disposal cost

• Easy system set up

• Less cost of maintenance

SPECIFICATION PARAMETER

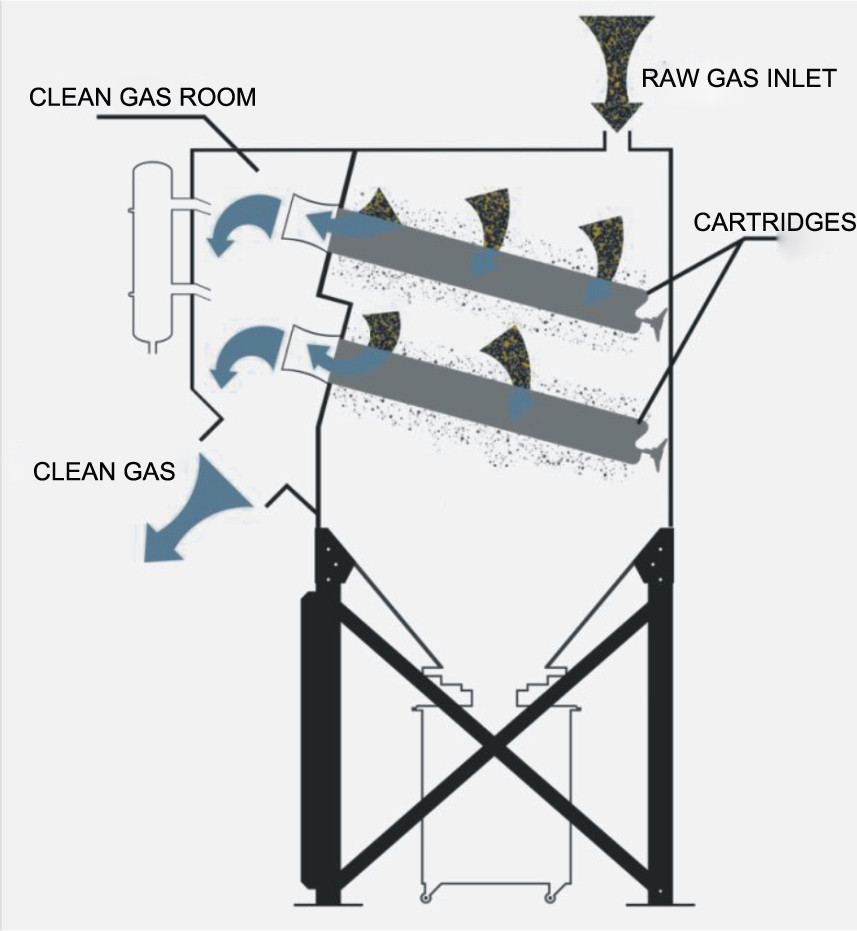

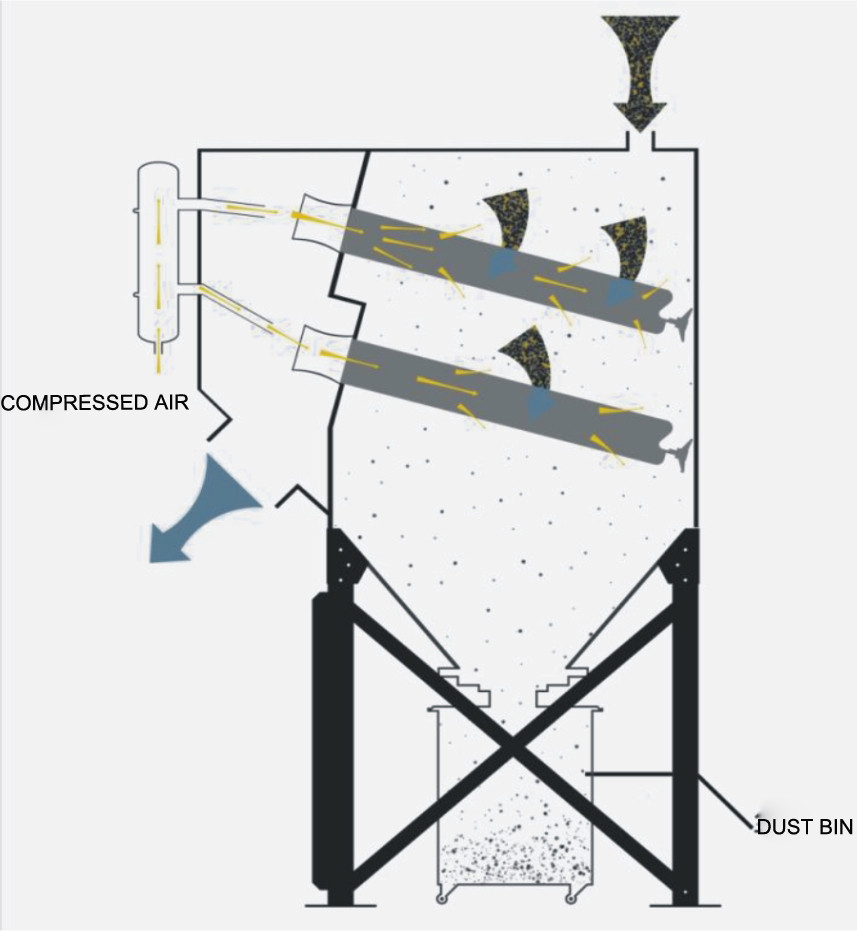

OPERATION PRINCIPLE

NO. | Model | Air Volume(m³/h) | Wide | Deep | Weight(kg) |

1 | TE-2-8 | 3600-7200 | 80 | 1000x2200x3320 | 0.999 |

2 | TE-2-16 | 7200-14400 | 160 | 2000x2200x3320 | 0.999 |

3 | TE-2-24 | 10800-21600 | 240 | 3000x2200x3320 | 0.999 |

4 | TE-3-12 | 5400-10800 | 120 | 1000x2200x3790 | 0.999 |

5 | TE-3-24 | 10800-21600 | 240 | 2000x2200x3790 | 0.999 |

6 | TE-3-36 | 16200-32400 | 360 | 3000x2200x3790 | 0.999 |

7 | TE-4-16 | 7200-14400 | 160 | 1000x2200x4250 | 0.999 |

8 | TE-4-32 | 14400-28800 | 320 | 2000x2200x4250 | 0.999 |

9 | TE-4-48 | 21600-53200 | 480 | 3000x2200x4250 | 0.999 |

10 | TE-4-64 | 28800-57600 | 640 | 4000x2200x4250 | 0.999 |

11 | TE-4-80 | 36000-72000 | 800 | 5000x2200x4250 | 0.999 |

PRODUCT FAQ:

Q: What should provide when choosing suitable dust collectors?

A: Process summary sheet should be provided, for we need to know the dust collection summary for example: dust category (what? Flammable? Corrosive? Explosive? Temperature? Density?)

Q: How to confirm the airflow/air capacity and the pressure?

A: First, you should choose the airflow you needed, then confirm the air filtration velocity which depending on the dust density and type, at last, we can choose the suitable filtration area to find the suitable one. The most important thing is that the equipment could so tall or wide, so please confirm the install area.

Q: What should concern when use central collection?

A: So many points should be sucked into one dust collector, first, the pressure and air flow distribute should be concern first. Second, when shut down some points or open more points will influence the whole system.

Contact Us

Wechat

+86 19550289881

Info@dustscrubber.com

+86 18768123711

Related Products

Please send your message to us

- Tel

- *Title

- *Content

Love discounts? Subscribe to newsletter!

subscription

Send Inquiry

Please send your message to us

- Tel

- *Title

- *Content

Company

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Web