Fluid Bed Dryer Granulator Coater Dust Collector-Design for STV Machine Company

Fluid Bed Dryer Granulator Coater Dust Collector-Design for STV Machine

Fluid Bed Dryer Dust Collection

Fluid Bed Dryer, granulator or coater is widely used in powder manufacturing, like chemical industry, pharmaceutical industry, food industry...

At the head of the equipment, there are several filter bags to serve as first filtration step, avoiding to much powder come out from the fluid-bed.

but that is not enough, it normally need second filtration step to meet the emission standard and prevent the dust come into the centrifugal fan.

In addition, the secondary dust collection unit should need low pressure. customer also need HEPA to meet pharmaceutical emission standard.

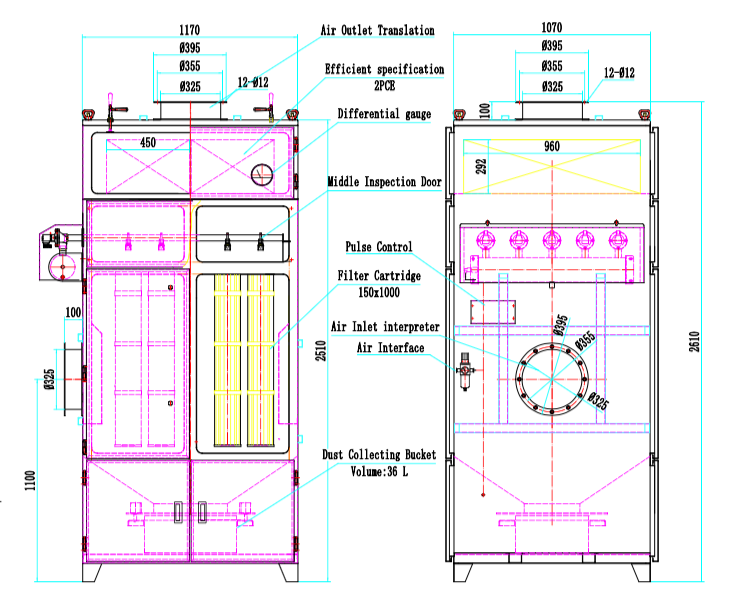

ACMAN design

Dust collector should need use stainless steel material, because it will applied in the pharmaceutical factory.

After the raw gas came out from the Fluid Bed Dryer, it come into ACMAN dust collector, and filtered by the cartridge filters then HEPA as second filter, the dust collector also have automatic pulse-jet system to clean the cartridge filters.

Normally, the Fluid Bed Dryer use high pressure blower, so the equipment should sustain high pressure design.

Normally, the Fluid Bed Dryer use high pressure blower, so the equipment should sustain high pressure design.

The cartridge filters use TORY material from Japan which have high efficiency, The Hepa brand is AAF.

In addition, customer ask us to set a DOP testing port to testing the leakage of dust.

Now, the customer had purchased 4 times and running so well.

Equipment Details