Home / All / Power Coating Machine/Powder Spraying System /

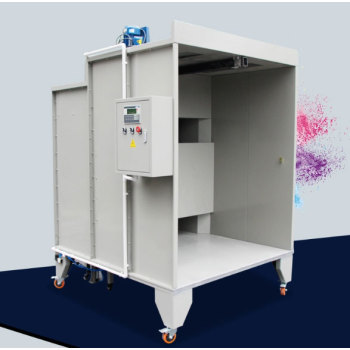

L Powder Coating Booth Manufacturers, Small Powder Spray Booth, Coating Booth for Metal Wheels

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

L Powder Coating Booth Manufacturers, Small Powder Spray Booth, Coating Booth for Metal Wheels

| Categories | Power Coating Machine/Powder Spraying System |

|---|---|

| Brand | ACMAN |

| Model | Powe-L |

| Update Time | Apr 3,2025 |

Detail Information

L Powder Coating Booth Manufacturers, Small Powder Spray Booth, Coating Booth for Metal Wheels

Powder Recycle Rate Reach 99%

This ACMAN POWE powder coating spray booth are consists of 8 systems:

1: Open Type Cabinet Body: Depending on different size of workpiece, ACMAN designed for 4 different size booth fitting for the clients requirements;

2: Filtration System: The filters is back installed on the booths which provide excellent filtration performance, the pleated offers 3 times of filtration area than traditional filters, whose powder recycle rate could reach 99%.

3: Filter Self-Cleaning System: POWE spray booth could clean the filter automatically. Thanks to the pulse jet cleaning system, the filters do not have risks of blocking;

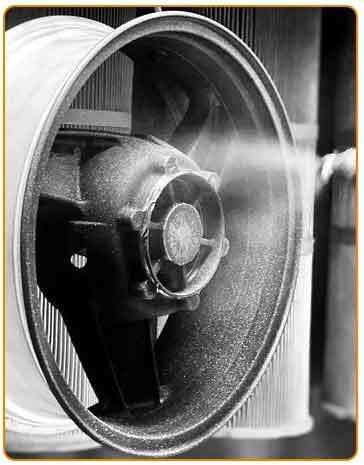

4: Centrifugal Fan system: The centrifugal fan provides big airflow and static pressure which making the system in a negative pressure atmosphere and could guarantee the powder not flying out;

5: Control System

Electric Control we use PLC, which could working smartly and data reveals directly.

It could control centrifugal fan running and stop, pulse

jet cleaning mode change and ect.

6: Powder Discharge System

The smart design of power discharge system consist of big volume dust drawer, wheels and a pneumatic sealing system.

pneumatic sealing system could separated the dust drawer directly.

7: Rail-mounted Hanger

The hanger could move on the top and easy for hanging the workpiece.

8: Lighting System

We design the lights which could lighting the cabinet inside and also a cover to protect the lights.

Details & Technical Data

|

Model

|

POWE-2315

|

|

Operation Size

|

width1500 * depth1000 * Height1700 mm

|

|

Overall Size

|

width1600 * depth2000 * Height2250 mm

|

Power Supply | AC 220V/380V (can be customized) |

Frequency | 50-60 HZ |

|

Power Consumption

|

2.2KW

|

Air Volume | 4000m3/h |

Filters | Polyester |

Filter Count | 3pcs(325*900mm) |

Filter Cleaning System | pulse-jet system |

Machine Weight | 300kg |

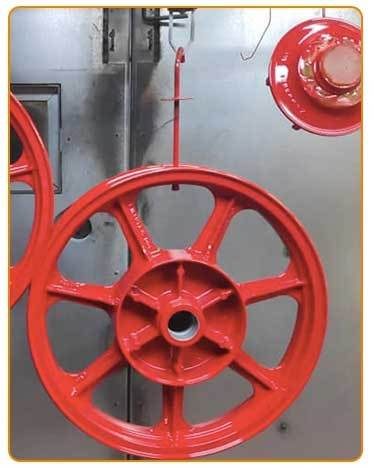

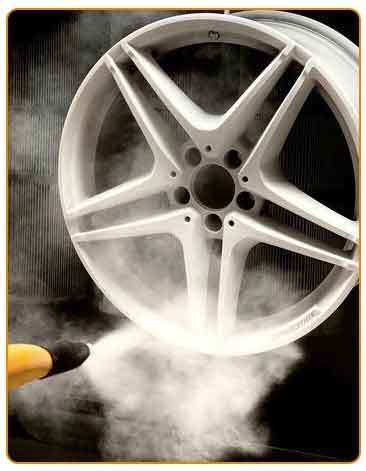

Applications

Contact Us

Wechat

+86 19550289881

Info@dustscrubber.com

+86 18768123711

Related Products

Please send your message to us

- Tel

- *Title

- *Content

Love discounts? Subscribe to newsletter!

subscription

Send Inquiry

Please send your message to us

- Tel

- *Title

- *Content

Company

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Web