Home / All / Central Vacuum Cleaning System/Unit /

Central Vacuum Cleaning System, Industrial Centralized Vacuum Systems

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Central Vacuum Cleaning System, Industrial Centralized Vacuum Systems

| Categories | Central Vacuum Cleaning System/Unit |

|---|---|

| Brand | ACMAN |

| Model | Vac-system |

| Application | Industrial Vacuum Cleaning Work System |

| Filter Material | Delta 2 sinter-plated filters |

| Cleaning Mode | Pulse jet compressed air backflow |

| Compressed Air Source | 0.4-0.6MP |

| Power Supply | 380V/50HZ or Customize |

| FOB port | SHANGHAI/NINGBO |

| Terms of Payment | T/T |

| Update Time | Mar 14,2025 |

Detail Information

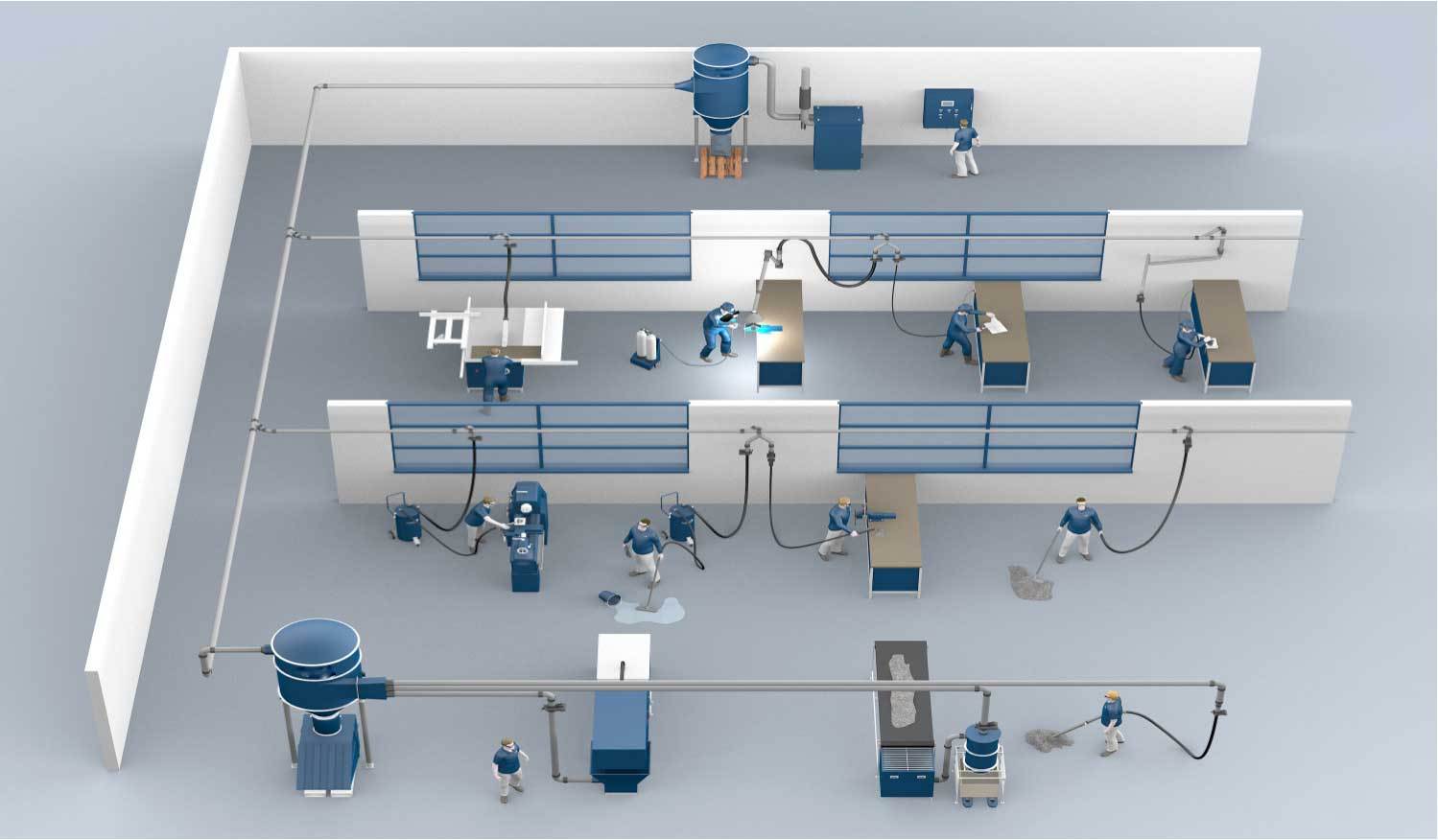

Central Vacuum Cleaning System, Industrial Centralized Vacuum Systems

Industrial Vacuum Cleaning System

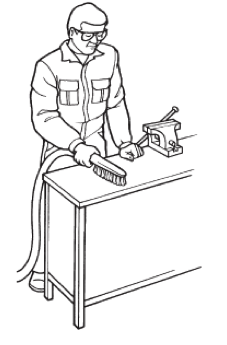

This central vacuum cleaning system is including a centralized waste receiving hopper and a vacuum pump. The centralized waste receiving hopper has a set of surface filter to catch the dust and also have a on-line pulse jet cleaning system to keep the filters cleaning by a pulse controller. The vacuum pump will provide an ultra-high pressure to convey the thin duct dust or material.

The extracted materials are pneumatically conveyed to a separator for final disposal.Also, the pressure differential gauge will monitoring the pressure online. Centralized vacuum systems we ACMAN called "VAC-SYSTEM"

Working Application

It designed to improve sanitation in food, dairy and pharmaceutical processing facilities by eliminating the inconvenience of portable vacuum cleaners.

Technical Data

|

Model |

Airflow (m3/h) |

Power(kw) |

Filter Area (m2) | Max Pressure (Pa) | Body Size (mm) | Inlet Size (mm) |

Port Available |

|

VAC-500/4 |

300 |

2.2 |

6.28 | 38000 | Dia 700*2010 | Φ57 |

2 |

|

VAC-500/6 |

500 |

7.5 |

9.42 | 60000 | Dia 800*2185 | Φ76 |

3 |

|

VAC-1000/6 |

1000 |

11 |

18.84 | 90000 | Dia 800*6185 | Φ89 |

7 |

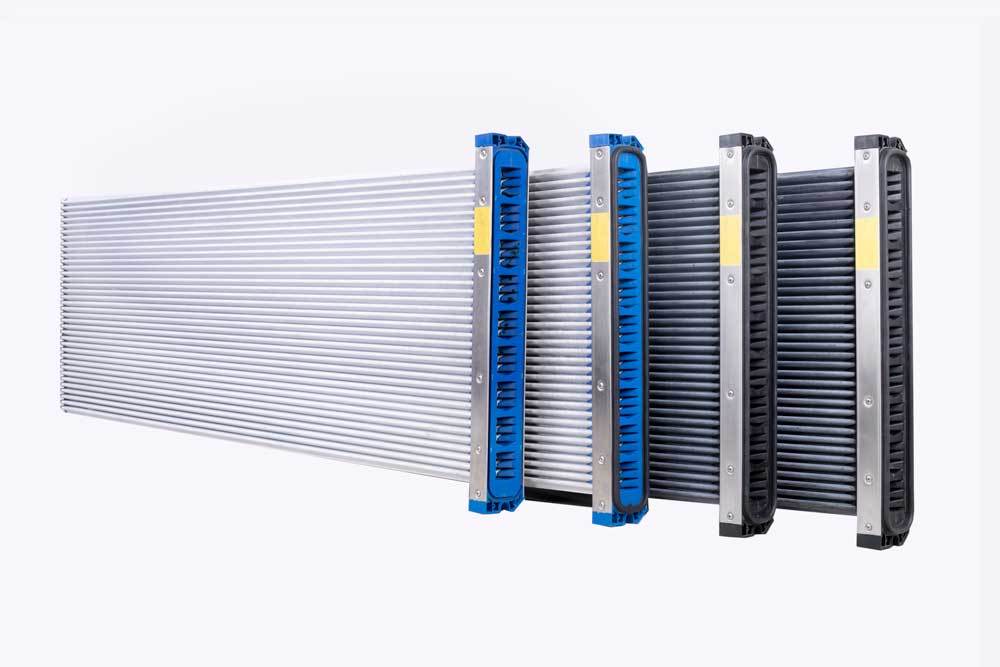

About the DELTA 2 Surface Filters

Sintered-plate Filters

This system's filters are special. It is not filter bags or cartridge pleated filters, The filter material is Sinter-plated Filters DELAT2.

Features:

1: The filter life span: 10 years;

2: Efficiency: H11@0.03um

Contact Us

Wechat

+86 19550289881

Info@dustscrubber.com

+86 18768123711

Related Products

Please send your message to us

- Tel

- *Title

- *Content

Love discounts? Subscribe to newsletter!

subscription

Send Inquiry

Please send your message to us

- Tel

- *Title

- *Content

Company

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Web