Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Sandblasting Room Air Ventilation Dust Collection System

| Categories | Sandblasting Dust Collector |

|---|---|

| Brand | ACMAN |

| Model | TR-150B-J |

| Application | Industrial Dust/fume Extraction |

| Filter Material | Polyester Cartridge Pleated Filters |

| Cleaning Mode | Pulse jet compressed air backflow |

| Compressed Air Source | 0.4-0.6MP |

| Jet Control | Timer/pulse controller |

| Power Supply | 380V/50HZ or Customize |

| FOB port | SHANGHAI/NINGBO |

| Update Time | Apr 3,2025 |

Detail Information

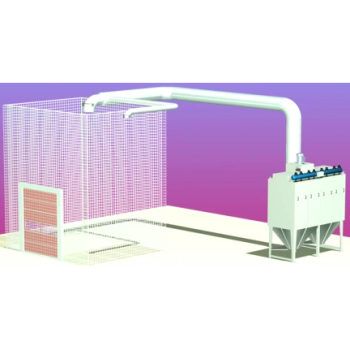

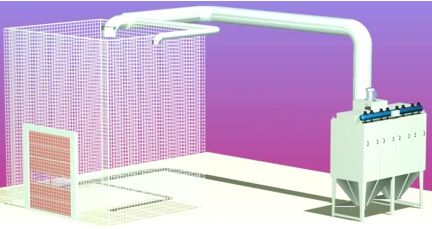

Sandblasting Room Air Ventilation Dust Collection System

ACMAN has a dust collector unique for small sandblasting machine, but some customers have big sandblasting room, and need to control the dust in a whole room.

We also have our solution for this. It should divide into two parts: first, sanding material recycle system, second, whole sanding room ventilation dust control system.

1: sanding material recycle system: the sanding material should be recycle by a cyclone, then the cyclone feeding the material to the sanding tank, the fine dust will take out to the dust collector;

2: whole sanding room ventilation dust control system: The airflow should depending on the room size and exchange rate of the ventilation time.

we have our cases sharing on our blog: https://www.dustscrubber.com/n1856084/Sandblasting-Dust-Control-Plan-King-Vehicle-Company-Sand-Blasting-Room-Dust-Collection-System-Design.htm

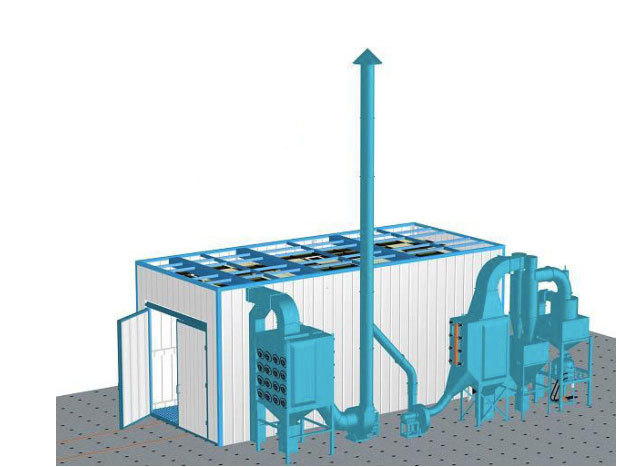

There are 2 blasting rooms in this project. Designed with main dust removal system + cyclone separator, filter and fan are put separately

It is placed outside the enclosure wall of the plant, and pipes are installed along the columns and walls of the plant.

Dust removal host: The design total air volume is 12,500m3/h;

1):16-ton sandblasting room: length, width and height = 3.3 x 4.0 x 5.2 = 68.6 m3; air changes is 60 times per hour x 2 = 120 times; Design of suction air volume of each blasting room: 120 x 68.6 about 8232 m3/h;

2):Total air intake of the spray booth: 8232 x 1.2 (coefficient) = 10,000 m3/h;

3)Pill separation room: dust removal air volume Ø200 pipe suction dust, 2,500 m3/h;

Dust removal host: The design total air volume is 12,500m3/h;

1):16-ton sandblasting room: length, width and height = 3.3 x 4.0 x 5.2 = 68.6 m3; air changes is 60 times per hour x 2 = 120 times; Design of suction air volume of each blasting room: 120 x 68.6 about 8232 m3/h;

2):Total air intake of the spray booth: 8232 x 1.2 (coefficient) = 10,000 m3/h;

3)Pill separation room: dust removal air volume Ø200 pipe suction dust, 2,500 m3/h;

Contact Us

Wechat

+86 19550289881

Info@dustscrubber.com

+86 18768123711

Please send your message to us

- Tel

- *Title

- *Content

Love discounts? Subscribe to newsletter!

subscription

Send Inquiry

Please send your message to us

- Tel

- *Title

- *Content

Company

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Web