Home / All / Bag In Bag Out Filter System /

Self-cleaning Bag In Bag Out Pulse-jet Collector, BIBO Cartridge Dust Collector Unit

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Self-cleaning Bag In Bag Out Pulse-jet Collector, BIBO Cartridge Dust Collector Unit

| Categories | Bag In Bag Out Filter System |

|---|---|

| Brand | ACMAN |

| Model | AC.Safe2 |

| Update Time | Nov 22,2024 |

Detail Information

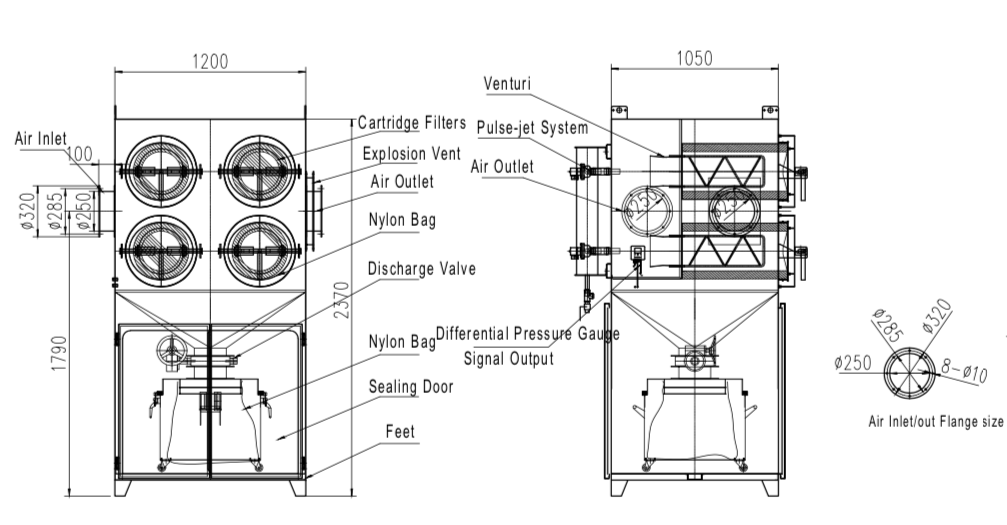

Self-cleaning Bag In Bag Out Pulse-jet Collector, BIBO Cartridge Dust Collector Unit

The Bag In Bag Out pulse jet collector (AC.Safe 2) is a security unit where the workers and the environment are completely safe for the cartridge filter exchange, needed due saturation of the cartridge filter or lifetime.

By having its internal access door fully sealed and not exposure, allowing to replacement, cleaningness, and disinfect regularly, the AC.Safe 2 whole body of the machine, according to principal concepts established by good manufacturing practices GMP's, and bio-containment concepts.

Features

1:High safety of work:

With the bag in bag out(BIBO) Devices equipped in the dust collector, the cartridge filters exchanging work facing with dust side could reduce the risk of exposure of contaminated/ hazardous powders.

2:Differential pressure gauge:

Differential pressure gauge with screen and output signal point could test the pressure avoiding leakage of harmful dust like pharmaceutical active ingredients.

3:Small installation Area:

the side setting cartridge filters lower down the height of the bag-in and bag-out filters unit, the big filter area make the BIBO filter system became smaller.

4:Negative pressure design:

The AC.Safe2. filtering system unit could sustain -3000Pa pressure.

5: High dust collection performance:

The cartridge filter is polyester material with PTFE coating, reaching H10 standards.

The cartridge filter is polyester material with PTFE coating, reaching H10 standards.

The filter material could choose TORAY material to escalate the filter material standards.

6: Self-cleaning system

Self-cleaning air backflow system will prolong the cartridge filters, and make the pressure stable.

Self-cleaning air backflow system will prolong the cartridge filters, and make the pressure stable.

Application

Pharmaceutical

• Contamination free

The powder collection in the active pharmaceutical production line

• Chemical hazard

The dust collection of the Medical agents having high physiological activity

• Chemical drug having high toxicity

• Hazardous material

• Nuclear industry

•Food and Cosmetics Industry,

•Food and Cosmetics Industry,

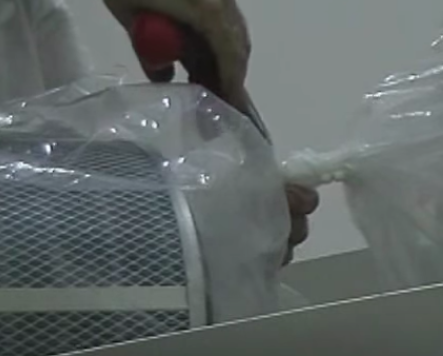

BIBO System Filter Exchange Steps

Step 1: Put on the safety bag

Step 2: pull out of the filter

Step 3: seal the waste filter and remove

Step 4: put on new bag with new filters

Step 5: remove the original bag, and pull into the new filter

Step 6: closed the door

Technical Parameter

|

Model.

|

Air Flow

m3/h |

Sustain Pressure | Filter Area m2 | Filter Size mm | Filter Quantity | Filter Material | Temperature |

Efficiency

|

Deashing Mode |

|

BIBO-F-1000

|

500-1000

|

-4KPaG | 18.5 | 350*660 | 1 | Complex Fiber | <120℃ |

F9

|

Pulse-jet |

|

BIBO-F-2000

|

2000

|

-4KPaG | 37 | 350*660 | 2 | Complex Fiber | <120℃ |

F9

|

Pulse-jet |

|

BIBO-F-4000

|

4000

|

-4KPaG | 71 | 350*660 | 4 | Complex Fiber | <120℃ |

F9

|

Pulse-jet |

Equipment Details

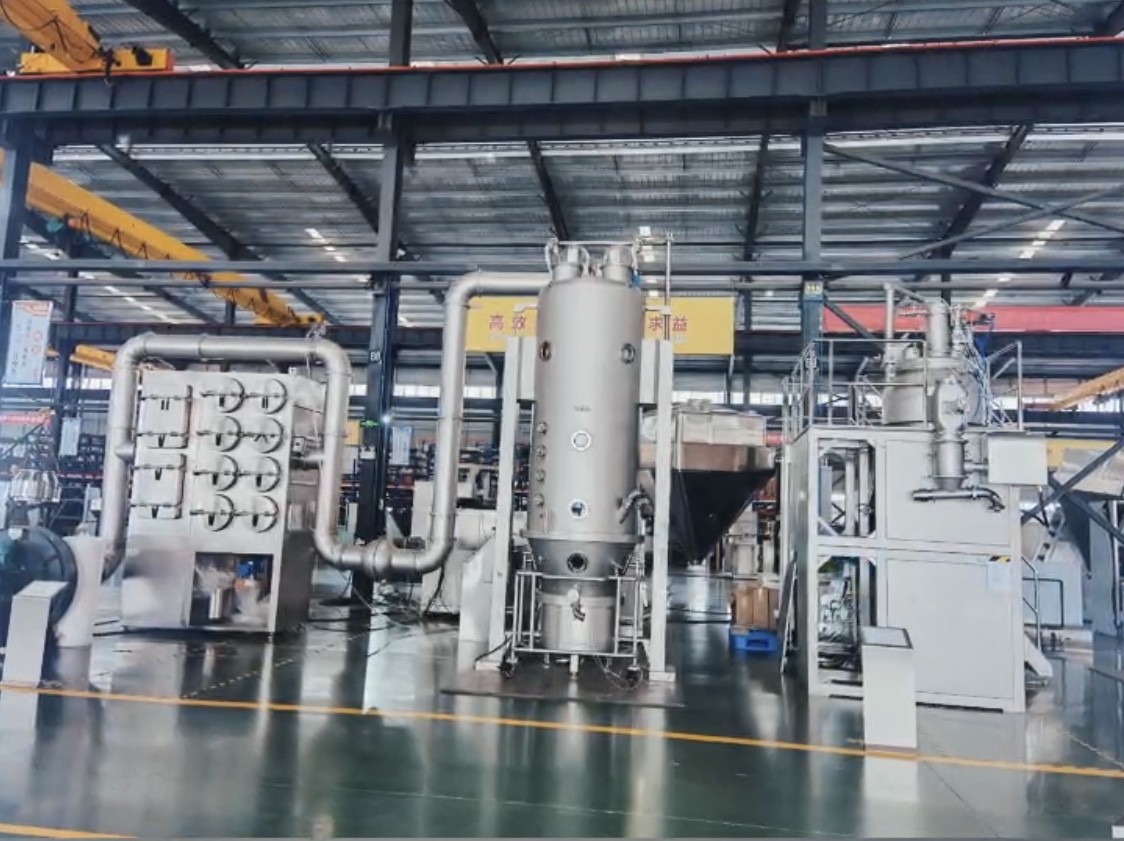

Fluidized bed BIBO filter unit application

Contact Email: Info@dustscrubber.com

Please send your message to us

- Tel

- *Title

- *Content

Love discounts? Subscribe to newsletter!

subscription

Send Inquiry

Please send your message to us

- Tel

- *Title

- *Content

Company

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Web