Home / All / Industrial Pulse Jet Dust Collector /

Cartridge Dust Collector Filter Unit without Fan-Blower Individual Setting

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Cartridge Dust Collector Filter Unit without Fan-Blower Individual Setting

| Categories | Industrial Pulse Jet Dust Collector |

|---|---|

| Brand | ACMAN |

| Model | TR-V |

| Application | Industrial Dust/fume Extraction |

| Efficiency | 99.9%(0.5um) |

| Filter Material | Polyester Cartridge Pleated Filters |

| Cleaning Mode | Pulse jet compressed air backflow |

| Compressed Air Source | 0.4-0.6MP |

| Jet Control | Timer/pulse controller |

| Power Supply | 380V/50HZ or Customize |

| FOB port | SHANGHAI/NINGBO |

| Terms of Payment | T/T |

| Update Time | Apr 3,2025 |

Detail Information

Cartridge Dust Collector Filter Unit without Fan-Blower Individual Setting

This dust collector is designed for dust high concentration working condition, which has big dust hod and dust bucket.

The centrifugal fan can individually set aside. The whole body also contains several cartridge filters to enlarge the filter area that can promote the filtration efficiency, avoiding block risks. Comparing with the bag filters, it has more filter area and the structure could be more smaller which save space in some small factory.

The body also have strengthening rib, so that if the centrifugal fan have ultra high pressure, it also could working smoothly and do not have shell deformation risks.

On the top of the dust collector unit, it has a pulse-jet cleaning system to confirm the dust extractor working in a steady differential pressure, keeping the system working continuously.

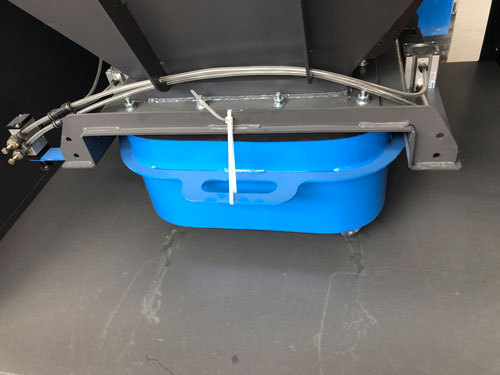

The dust bin has an air cylinder design, leakproofness is strengthened.

Feature and Application

1:used for high dust density condition;

2:used for hight limits conditions.

3:used for high pressure blower suction condition;

4:used for dust recycle condition.

Application:

1:Drying machine secondary dust collection;

2:Fluidized bed coating machine dust collection;

3:Powder collection in powder feeding;

3:Powder collection in powder feeding;

4:cutting machine dust collection;

5:Packaging dust collection

....

Contact Email: Info@dustscrubber.com

Related Products

Please send your message to us

- Tel

- *Title

- *Content

Love discounts? Subscribe to newsletter!

subscription

Send Inquiry

Please send your message to us

- Tel

- *Title

- *Content

Company

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Web