Home / All / Dust Collection Auxiliary Equipment /

Manual Powder dumping machine/bag feeding station

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Manual Powder dumping machine/bag feeding station

| Categories | Dust Collection Auxiliary Equipment |

|---|---|

| Brand | ACMAN |

| Update Time | Mar 14,2025 |

Detail Information

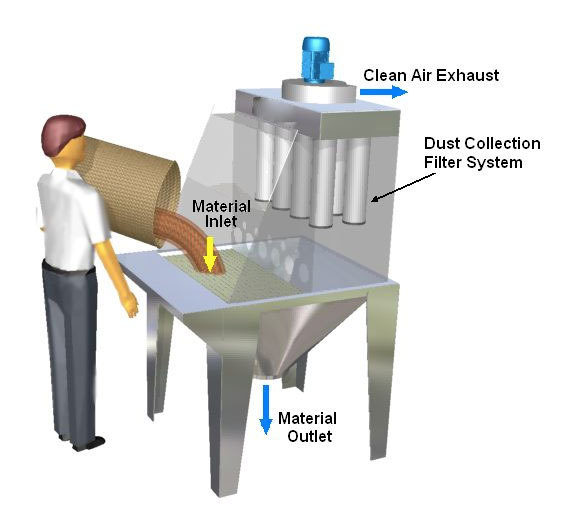

Manual Powder dumping machine/bag feeding station Detail:

• Features:

1:It is not easy to blocking material, which also can choose dust collector to reduce dust flying to protect environment and reduce labor intesity

2:The activated hopper is installed at the bottom of the storage tank, and it can be selected according to the size of storage bin.

3:It solves the problem of blocking of elastic granules and powders and has good durability.

• Work principle:

Dust-free feeding station or bag dump station mainly solves the dust problem in dumping process of small bags of powdery or granular materials in medicine, food, chemical and other industries. The dust generated in the unloading operation is automatically sucked and filtered by the dust removing device arranged above above the feeding station to ensure the safety and cleanness of the operator and the environment.

• Power intake:

" milk powder, granulated sugar, powder, seasoning powder, silicon powder, etc., and is used for manually disassembling and dumping material bags, so as to the materials fall into the storage hopper by gravity."

SPECIFICATION PARAMETER

Mode | Feed amount | Vibration motor(KW) | Dust removing fan(KW) | Back blow bag(L) | Noise(db) | Filtering accuracy | Weight(kg) |

WT-100 | 400-1000 | ---- | 1.1 | 5.5 | 75 | 0.98 | 150 |

WT-200 | 500-3000 | ---- | 2.2 | 5.5 | 75 | 0.98 | 130 |

APPLICATION:

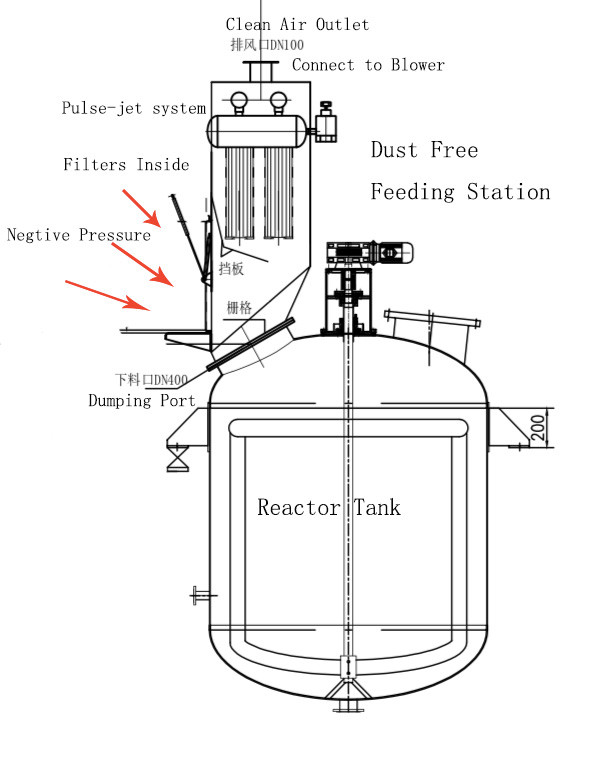

Dust Free Reactor Bag Dumping Solution

Reactor kettle used in chemical and pharmaceutical industry usually has dust problem while bag dumping or powder filling.

Traditionally, people use a portable dust collector which a dust extraction hood, this is a easy way, but do not convenient in some platforms.

so ACMAN design a dumping station link with the reaction, which installed with filters, pulse-jet cleaning system, and making the feeding process continuously, dust-freely.

It is also widely used in blenders, reaction kettles, powder feeding process...

PRODUCT FAQ:

Q: This feeding station has blower?

A: This dust-free bag dump station is NO-STANDARD size, some need the blower, some want to link to their central dust collection system, some want the offline pulse jet to clean the cartridges, some no needs, the size and dumping size is also can design for your needs.

Q: What is the filter material?

A: PE cartridges.

Q: Where need the Powder dumping machine?

A: Feeding material tank, blending tank….

Video

Contact Us

Wechat

+86 19550289881

Info@dustscrubber.com

+86 18768123711

Related Products

Please send your message to us

- Tel

- *Title

- *Content

Love discounts? Subscribe to newsletter!

subscription

Send Inquiry

Please send your message to us

- Tel

- *Title

- *Content

Company

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Web